Headlines

Japan's Mitsubishi Corp looks to invest in nickel, lithium projects

Originally posted on Reuters.com

The signboard of Mitsubishi Corp is pictured at its head office in Tokyo, Japan August 2, 2017. REUTERS/Kim Kyung-Hoon

TOKYO, April 13 (Reuters) - Japanese trading house Mitsubishi Corp (8058.T) is looking to invest in nickel and lithium projects to meet growing demand for electric vehicle (EV) batteries, while boosting its copper output, the head of its metal operations said on Thursday.

The move comes as global push by automakers to electrify their fleets has sparked a rush for stable supplies of lithium, nickel and copper and other critical minerals. Demand is expected to exceed supply by the end of the decade.

"As global resource companies and others are looking for lithium and nickel, we are considering to invest in the two metals," Satoshi Koyama, Mitsubishi's mineral resources group CEO, told an analysts meeting.

Canada and Australia could be investment targets for nickel as they meet both the criteria of safety from the perspective of geopolitical risk and access to renewable power from the perspective of decarbonisation, he said.

Last year, Mitsubishi bought a 15% stake in a joint venture with Giga Metals Corp (GIGA.V) to pursue the development of the Turnagain nickel deposit in Canada.

"We are verifying what kind of nickel projects will make it to the profitability line, given technical hurdles and cost issues," Koyama said.

Mitsubishi is also looking into a number of lithium projects.

To develop a new mine, it must come with the downstream operation to process the metal into raw battery material, but whether it can be done in Australia and North America will be the biggest challenge, Koyama said.

Mitsubishi and its joint venture partner BHP Group (BHP.AX) in Australia have put up for sale their Daunia and Blackwater metallurgical coal mines in Queensland's Bowen Basin.

"If the deal comes through, we may allocate the cash into growth segments such as copper and battery metals," Koyama said.

Mitsubishi, which owns a stake in five copper mines in South America, including 40% stake in Anglo American's (AAL.L) Quellaveco mine in Peru, wants to bolster its copper output by expanding the existing mines and investing in new promising projects, Koyama said.

Reporting by Yuka Obayashi; Editing by Kim Coghill

Canada’s budget measures brighten funding prospects for critical miners

Originally posted on Mining.com

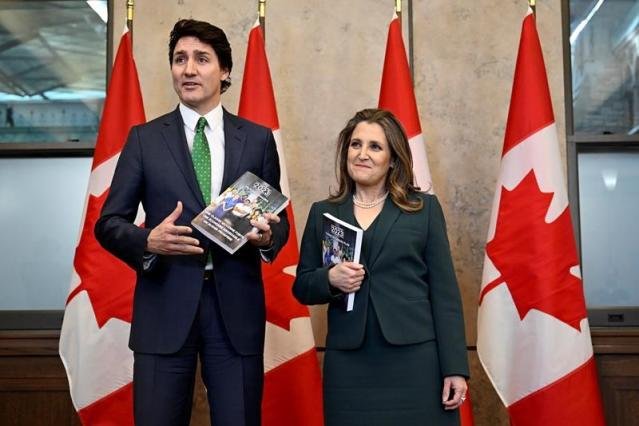

Canada’s move to expand the investment tax credit for mining companies to align it with policies in the United States is accelerating funding talks for critical miners, company executives told Reuters.

Prime Minister Justin Trudeau’s government proposed a 30% investment tax credit for expenses related to the exploration of critical minerals in the latest budget announced last month. This incentive also covers investors planning to buy shares in certain critical mining companies such as those in the exploration of lithium brine.

Company executives say the new measures would help bring in new equity investors who stayed away from the mining sector due to volatile capital market conditions. An early-stage exploration project typically needs between C$10 million ($7.4 million) to C$25 million, according to industry estimates.

“These provisions are going to be of huge help to attract investments,” said Mark Selby, CEO of Canada Nickel Company Inc.

Since the budget announcement, Selby said Canada Nickel’s ongoing discussions for a potential partnership with an unidentified Korean battery maker have accelerated thanks to the specific measures. The TSX Venture Metals and Mining Index is up 4% since the budget, compared with a 2.7% rise in the broader market.

Canada is trying to match the incentives announced by the United States under the Inflation Reduction Act which offers a combination of tax credits and government loans worth $40 billion to support critical mineral projects.

Canada is home to half of the world’s mining companies and is seen as a premium destination for junior miners to raise capital, according to The Toronto Stock Exchange.

Chris Doornbos, CEO of Alberta-based E3 Lithium, said the government’s proposals open up a whole new funding option for junior miners in Canada that was not available before. E3 Lithium is working on the exploration of lithium from brines in Calgary.

“So you actually get better value for the money (raised through flow-through shares) and now there’s more of that which is available,” Doornbos said.

The flow-through shares are a specific feature in the Canadian capital market, where listed mining companies raise equity at a higher price from investors for exploration projects, and investors in turn claim tax rebates. This helps attract investments in risky exploration projects, company executives say.

Several junior mining companies in western Canada are optimistic about the fund raising prospects and are in talks with banks for financing, Doornbos added.

“At Litus we are excited about how this initiative will further ignite the strategic battery metals sector,” said Ghada Nafie, CEO and Co-Founder of Litus, a Calgary-based company working on a technology to extract lithium.

TSX, Canada’s biggest stock exchange operator, sees the new budget proposals as “very positive” for the mining sector but warned that broader economic uncertainty and geo-political risks are dominating investor sentiment, Dean Mcpherson, the Head Global Mining, TSX told Reuters.

Still, the mining industry has a reason to cheer.

“These measures do level the playing and put us in a stronger position,” said Pierre Gratton, CEO of the Mining Association of Canada.

($1 = 1.3488 Canadian dollars)

(By Divya Rajagopal; Editing by Alistair Bell

Canada is sitting on a critical minerals mother lode. But is it ready for the new gold rush?

Originally posted on Cbc.ca

Drive two hours north of Ottawa, put on a hard hat and bright orange vest, descend into a pit — and you find yourself on the frontline in the fight to be part of the new, green economy.

A mining project might not be what comes to mind when you think of the transition to a lower emissions economy. But embedded in electric vehicles, solar panels and hydrogen fuel storage are metals and minerals that come from mines like the one in Lac-des-Îles, Que.

The graphite mine, owned by the company Northern Graphite, is just one of many projects aimed at extracting what are now officially dubbed "critical minerals" — substances of significant strategic and economic importance to the future of national economies.

Lac-des-Îles is the only significant graphite mining project in North America, accounting for Canada's contribution to an industry dominated by China.

Hugues Jacquemin and Kirsty Liddicoat of Northern Graphite take The House on a tour of their mine in Quebec, and talk about what Canada needs to do to lead the way on critical minerals development.

Experts and industry proponents say Canada has the potential to be a major player in critical minerals — but it needs to change the scope and scale of investment and regulation in order to get there.

For Northern Graphite, in the short-term, that means money. Hugues Jacquemin, Northern Graphite's CEO, told CBC's The House during a tour of the Quebec facility that the company is trying to open a mine in Bissett Creek, Ont., to produce graphite that could go into EV batteries.

But they need to raise $150 million to kick-start production.

Hugues Jacquemin, CEO of Northern Graphite, stands in a pit mine nearing the end of its commercial life in Lac-des-Îles, Que. (Jennifer Chevalier/CBC)

"No investor is willing to take 100 per cent of the risk. We need someone to step in alongside the investor and support part of the risk because today there is no demand for battery materials in Canada or in the U.S. at the moment," Jacquemin said.

"So we need something to help us jump-start the whole supply chain so that we can be there three or four years from now, when the market is buying materials."

The company says it expects to seek significant financial support from the federal government, but nothing has been confirmed so far.

For its part, the federal government says it's committed to helping build a critical minerals industry in Canada and recently released its official strategy to do so.

"We need to ensure that we have access to these critical minerals to be able to successfully go through the energy transition and fight climate change," Natural Resources Minister Jonathan Wilkinson said in an interview with The House.

Wilkinson told host Catherine Cullen that while the government is willing to work with companies, it can't be the only source of funding.

"The source of all capital doesn't come from the government. Government can actually do things to help kick-start those [projects]. But obviously companies need to be able to [raise] private capital," he said.

Wilkinson pointed to a number of measures the government has in place to help Canadian companies develop critical minerals projects, including the Canada Growth Fund, new tax credits for green investments and government funding for infrastructure to help facilitate projects.

Project timelines a concern

The Canadian government is far from the only one interested in critical minerals mining in this country. The U.S. Department of Defence has expressed interest in projects here — and a willingness to invest. Jacquemin said Northern Graphite plans to apply for American investment as well.

Critics — including Conservative Leader Pierre Poilievre — have said it simply takes too long to develop a mining project in Canada. Northern Graphite, for example, has owned Bissett Creek since 2012, and the mine is not yet operational.

Wilkinson said the average mining project typically takes around 12 to 15 years but "that's still too long." He said the government is aiming for something more like five or six years.

CBC News: The House49:39Mission critical: Is Canada lagging behind in the critical minerals race?

The House takes an in-depth look at Canada’s efforts to become a leader in the development of critical minerals. Hugues Jacquemin and Kirsty Liddicoat, executives of Northern Graphite, explain their efforts to expand. Natural Resources Minister Jonathan Wilkinson explains how the government is responding. Mark Podlasly talks about his efforts to help First Nations secure their interests, and experts Nate Wallace, Alisha Hiyate and Ian London weigh in on what Canada should be doing to respond to what some are calling the new gold rush.

Ian London, executive director of the Canadian Critical Minerals and Materials Alliance, told Cullen that Canada has the "pieces of the puzzle" to unlock Canada's critical mineral potential, but more needs to be done.

"Prospective customers … want operating facilities, not aspirations," he said.

Environmental impact, Indigenous participation

Perhaps the most significant challenges to the mining industry come from concerns about environmental impacts and the role of Indigenous communities.

On the environmental front, advocacy groups like Environmental Defence worry that mining projects carry with them dangers of waste and environmental damage.

"We need to recognize that more mining likely needs to happen, but it needs to be governed responsibly, and we can't use the rush to extract more minerals for the transition to be an excuse for watering down environmental standards," said Nate Wallace, a program manager with the group.

Ontario Premier Doug Ford shows a draft agreement with Chief Cornelius Wabasse of Webequie First Nation, left, and Marten Falls Chief Bruce Achneepineskum, centre, in March 2020 after signing an agreement to move forward on building the Northern Road Link in the Ring of Fire area. (Nathan Denette/The Canadian Press )

Wallace noted that with some projects, there's a risk that the benefit of unlocking reduced emissions from innovations like electric vehicles would not be worth the cost of the project's greenhouse gas output. He cited the controversial Ring of Fire proposals in Ontario as one example.

"There's also significant environmental concerns about that project because it's covered by peatlands, and that's basically equivalent to Canada's Amazon rainforest, in terms of being a massive carbon sink," he said.

London said he agrees that a balance needs to be struck between environmental impacts and developing projects. He said that dialogue should continue on controversial projects, but Canada's focus should be more immediate.

"Our priority should be set on projects which are closer to — not shovel ready — but actually going into production," he said.

Wilkinson said the government is "very focused" on making sure the environmental cost of mining is minimized.

"There is no such thing as a mining project that has zero impact," he said. "But there certainly are projects that can be done in a way where the impacts are modest and that there is a plan for how you remediate in the aftermath of the mine."

The Ring of Fire proposals are also a key test of how governments and companies interact with Indigenous communities. The Neskantaga First Nation has said it was not meaningfully consulted on the proposals and has protested them.

First Nations take their message directly to Ontario government — no resource extraction without consent

Watch this uncut exchange as leaders from five First Nations in northwestern Ontario and NDP MPP Sol Mamakwa speak to reporters after demonstrating their continued opposition to mining in the Ring of Fire without their prior consent at Question Period.

Mark Podlasly, an executive with the First Nations Major Projects Coalition, acknowledged that Indigenous people have been wronged in the past when it comes to development.

"Many First Nations are concerned that this new rush for critical minerals, towards the net zero transition, is going to be a repeat of what's happened in the past," he told Cullen.

"How it should work is Indigenous people have to be included in the environmental and economic decisions of the projects from the start."

Mining faces a reputational challenge

Kirsty Liddicoat, Northern Graphite's COO, said the mining industry also faces challenges when it comes to building up its own reputation and workforce. Along with domestic concerns, Canadian companies are frequently criticized for their actions overseas.

"I think mining as an industry is poorly understood and it doesn't necessarily have the best reputation. So that's leading us to a number of challenges with social acceptability and talent," she said.

"We need to be attracting the smartest people to the biggest problems that we have as a world, to help us make this shift."

Kirsty Liddicoat, chief operating officer of Northern Graphite, holds a rock with graphite ore at the company's Lac-des-Îles mine. (Jennifer Chevalier/CBC)

Kirsty Liddicoat, chief operating officer of Northern Graphite, holds a rock with graphite ore at the company's Lac-des-Îles mine. (Jennifer Chevalier/CBC)

London said the mining industry has taken steps to build in more corporate responsibility but there will always be a tradeoff in an extractive industry.

"A colleague of mine said when it comes to green technologies, amongst all that green, there's always going to be a little black," he said.

"It is an extractive industry, there will be some negative impact. But overall, it's tremendously positive."

Factbox: Automakers accelerate the drive to secure battery raw materials

Originally posted on Mining.com

Rising demand for electric vehicles (EV) around the world is encouraging automakers such as Tesla Inc, Volkswagen and Stellantis NV to step up efforts to secure raw materials needed for making batteries.

Following are some of the deals major automakers have announced with suppliers and miners:

TESLA

26-Aug-2022 – Panasonic Holdings Corp, a supplier to Tesla, is in talks to build an additional EV battery plant in the United States at a cost of about $4 billion.

01-Mar-2022 – Australia’s Core Lithium will supply up to 110,000 dry metric tonnes of Spodumene concentrate, a chief source of lithium, over four years starting in the second half of 2023.

01-Nov-2021 – China’s Ganfeng Lithium will supply undisclosed volumes of battery-grade lithium for three years starting 2022.

22-July-2021 – Australia’s BHP Group will supply nickel from its plants in Western Australia. Quantities, timing not disclosed.

VOLKSWAGEN

26-Sept-2022 – Volkswagen announced a $2.9 billion battery parts joint venture with Belgian materials firm Umicore, becoming the latest European automaker to bring battery supplies closer to home in the shift towards electric vehicles.

23-Aug-2022 – Volkswagen intensified efforts to secure access to key battery materials lithium, nickel and cobalt by striking a cooperation agreement with top supplier Canada. No financial details were disclosed.

08-Dec-2021 – Vulcan Energy Resources will provide lithium hydroxide for five years starting 2026. Vulcan extracts lithium from geothermal sources in Germany’s Upper Rhine Valley region.

08-Dec-2021 – Belgium’s Umicore will supply cathode materials for Volkswagen’s European battery cell factories under a joint venture. It will start production in 2025 with 20 gigawatt hours for the carmaker’s plant in Salzgitter, Germany.

STELLANTIS

10-Oct-2022 – Carmaker Stellantis has signed a non-binding preliminary agreement with GME Resources to secure supplies of nickel and cobalt sulphate for electric vehicle batteries.

24-June-2022 – Stellantis will invest 50 million euros ($50.3 million) to buy an 8% stake in German-Australian start-up miner Vulcan, becoming its second largest shareholder and extending a lithium supply agreement to 10 years.

2-June-2022 – Controlled Thermal Resources will supply up to 25,000 metric tons per year of lithium hydroxide over 10 years from a project in California.

29-Nov-2021 – Preliminary deal with Vulcan for lithium produced using geothermal energy from Germany. Over five years starting in 2026, Vulcan will supply 81,000-99,000 tonnes of battery-grade lithium hydroxide.

RENAULT

1-June-2022 – Moroccan miner Managem will supply 5,000 tonnes of low carbon cobalt sulphate under a seven-year deal starting from 2025.

21-Nov-2021 – Vulcan will supply 26,000-32,000 metric tonnes of battery-grade lithium chemicals for initial six years starting 2026.

08-Oct-2021 – MoU with Finnish nickel and cobalt miner Terrafame to supply nickel sulphate. Quantities and timeline not disclosed.

MERCEDES BENZ

23-Aug-2022 – Mercedes-Benz strikes cooperation agreement with Canada to secure access to lithium, nickel and cobalt. It will explore a strategic partnership with Rock Tech Lithium (RCK.V) which would supply the carmaker and its battery partners with up to 10,000 tonnes of lithium hydroxide a year from 2026.

BMW

5-Aug-2022 – BMW signs a non-binding memorandum of understanding with European Lithium Ltd for the supply of lithium hydroxide.

7-June-2022 – U.S. startup Lilac Solutions, backed by BMW, was competing for mining partnerships in Bolivia to tap into the world’s largest resources of lithium.

TOYOTA

1-Aug-2022 – A joint venture of Toyota and Panasonic will buy lithium from ioneer Ltd’s Rhyolite Ridge mining project in Nevada to build EV batteries in the United States.

04-Oct-2021 – BHP Group will supply nickel sulphate from Western Australia to Toyota and Panasonic’s joint venture. Details were not disclosed.

GENERAL MOTORS

3-Aug-2022 – GM makes prepayment of $198 million to Livent Corp for a guaranteed six-year supply of lithium from 2025 at a contractual price per tonne. Volume not disclosed.

02-July-2021 – GM will make a “multimillion-dollar investment” in and help develop Controlled Thermal Resources Ltd’s Hell’s Kitchen geothermal brine project near California’s Salton Sea. The project could be producing 60,000 tonnes of lithium – enough to make roughly 6 million EVs – by mid-2024.

12-April-2022 – Miner Glencore will supply cobalt, secured from its Murrin Murrin operation in Australia, to be used in GM’s Ultium battery cathodes. Details were not disclosed.

FORD

22-July-2022 – Ioneer Ltd signs binding offtake agreement with Ford to supply lithium from Rhyolite Ridge in Nevada.

14-July-2022 – Ford Motor, SK On and SK Battery America create joint venture to build and operate an EV battery plant in Tennessee and two plants in Kentucky.

29-June-2022 – Australia’s Liontown Resources will supply up to 150,000 dry metric tonnes per year of spodumene concentrate, a source of lithium, from its Kathleen Valley project in Western Australia for five years starting 2024.

11-Apr-2022 – Ford signs preliminary deal to purchase 25,000 tonnes of lithium annually from Lake Resources’ Kachi project in northern Argentina.

22-Sept-2021 – Ford partners with startup Redwood Materials to form a “closed loop” or circular supply chain for electric vehicle batteries, from raw materials to recycling.

($1 = 0.9939 euros)

(By Bartosz Dabrowski, Ina Kreutz, Agnieszka Gosciak, Tristan Chabba, Dagmarah Mackos, Anastasiia Kozlova, Nilanjana Basu, Yuvraj Malik and Kannaki Deka; Editing by Susan Fenton and Bernadette Baum)

Can the Global Automotive Industry Source Enough Critical Minerals to Meet EV Production by 2030?

Originally Posted on InvestorIntel.com

American President, Joe Biden, has decreed, and the U.S. Congress has mandated, that, by 2030, 50% of new domestic American OEM automotive production must be of electric vehicles (EVs). Further, the U.S. government now requires by law that, by 2028, for a new EV purchaser to receive a tax credit of up to $12,500, then 80% of the vehicle’s components must have been made in the United States from raw materials produced and processed in the United States.

American OEM automakers are losing money hand-over-fist on making and selling EVs. Ironically, it is their profits from internal combustion engine (ICE) vehicles that are keeping them afloat. Without subsidies, also known as “tax credits,” no one could continue to make and sell EVs. And, quite frankly, without ICEs, Tesla could not afford to be in the EV business. The supply chains for universal automotive components used both by ICEs and EVs could not exist without the scale and sales of the ICE industry.

Sourcing Critical Minerals for EV production

I think that the idealogues, both elected and unelected, in North America and Europe need to answer some questions. Today I am asking, “How does the global non-Chinese OEM automotive industry plan to source enough critical minerals and metals, annually, to meet government-mandated, not market-driven goals for the production of EVs by 2030?

In the following discussion, I’m going to limit myself to the critical minerals and materials needed for the production of EVs just in the United States. Keep in mind that American domestic OEM automotive production is just 10% of the global annual total production.

The domestic American OEM automotive assembly industry most of which is owned and operated by foreign-owned manufacturers is building today, in North America, at least nine new factories to construct lithium-ion batteries for EVs. In addition, a half dozen EV drive train factories and a dozen assembly plants will be built or converted to pure EV production by the end of this decade.

Calculating the amount of Critical Minerals needed

The figures below are averages used in a variety of lithium-ion types. The only constants are for lithium and graphite, which are calculated for a 100 kWh Tesla battery no matter what the cathode chemistry.

The figures for material usage for rare earth permanent magnets are for one drive motor. American cars typically use two.

For the battery:

Note that the amounts above are annual needs for 50% of projected American domestic production using a production number baseline of 15,000,000 vehicles per year, which is more than 2022 production and sales but far less than the 21st-century average.

The material usage per vehicle comes from the most recent estimates of the International Energy Association (“IEA”).

Finally, note that the amount of lithium required, up to 60,000 tonnes, measured as metal, is equal to 360,000 tonnes, measured as lithium carbonate equivalent (LCE), which is more than half of the global production of LCE in 2022!

Assuming that 50% of global OEM automotive production in 2030 will be EVs, you need to multiply the above demand numbers each by a factor of between 5 and 10 just to assume that the total global production of vehicles remains the same in 2030 as today, about 100,000,000 vehicles per year.

The amount of lithium necessary for enough stationary storage to manage a world totally converted away from fossil fuels is estimated to be 3.5 times as much as is necessary for the conversion of the global automotive fleet, so you need to add that demand to the above totals. I do not know how much of the world’s energy production in 2030 will be from non-fossil fuels, but even if it is just 20% of the total the above demand numbers would double.

The question we need to ask…

The core questions are:

Can the world’s economies divert enough of their total capital and natural resources to effect the above transformation(s)?

Even, if so, are there sufficient resources of the critical minerals and processing capacity for transforming them into end user products to carry out even this percentage of the transformation in just 7 years?, and

Would even the attempt to transform the global energy production economy from fossil-fuels to alternate energy destroy wealth creation and its wide distribution bringing about the decline of the Western standard of living and the destruction of any hope that the developing world has of achieving that standard?

It’s time to decide if it’s all worth it.

Federal government outlines $83B in clean economy tax credits in bid to compete with U.S. incentives

Originally posted on ctvnews.ca

Serious money is heading for Canadian industries looking to reduce emissions after the federal government unveiled its answer to the U.S. Inflation Reduction Act.

The spending commitments announced in Tuesday's federal budget include tax credits for investments in clean electricity, clean-tech manufacturing, and hydrogen that together are expected to cost some $55 billion through to the 2034-35 fiscal year.

Details: Budget 2023 prioritizes pocketbook help and clean economy

Capital Dispatch: Sign up for in-depth political coverage of Parliament Hill

Total tax incentives amount to almost $83 billion over that timeframe when the carbon capture and storage and clean-tech investments credits announced last year are factored in, both of which saw minor boosts this round.

The government says the funding is necessary to boost clean economy spending from some $15 billion a year to the $100 billion a year needed. The spending is also needed to not fall behind as other countries roll out subsidies, most notably with the US$369 billion contained in the landmark U.S. legislation passed last year.

"In what is the most significant economic transformation since the Industrial Revolution, our friends and partners around the world, chief among them the United States, are investing heavily to build clean economies," said Deputy Prime Minister Chrystia Freeland as she introduced the budget.

Tax credits are the backbone of the effort because they are stable and efficient way to roll out government support, while leaving decision-making with the expertise of the private sector, said a senior government official in the budget lockup.

Clean electricity is the biggest focus of the credits, costing $6.3 billion over the first four years starting in 2024, and $25.7 billion through to the 2034-35 year. Notably, provincial utilities and Indigenous-owned corporations will be eligible for the credits.

The spending is meant to help spur both more generation, as well as a better-connected east-west grid to meet the expected doubling of electricity demand by 2050.

The clean electricity package is where the government has likely done enough to meet its goals, said Michael Bernstein, executive director of Clean Prosperity.

Other funding areas however, including the $11.1 billion in credits for manufacturing and $12.4 billion for carbon capture through to 2034, likely aren't enough to close the gap with what the U.S. is offering, he said.

"It really is one of those situations where your competitor has stepped up and said we are going to be providing an almost unthinkable amount of money."

Canada has opted for construction-focused project support, while the U.S. IRA covers operational costs with payments based on production volumes. It's like Canada is offering a single large cup of soda, whereas the U.S. is offering endless kiddy-cup sized refills, meaning Canada needs to offer a pretty big cup to compete, said Bernstein.

Since it's not covering operations, Canada needs to move quickly on offering the carbon pricing backstop that it's promised to develop in the budget, he said.

The so-called contracts for difference would provide certainty to industry on future carbon pricing and credits, but so far they're still in consultation, as are several other key policies.

"What surprised me was how many things are still left to be determined," said Rachel Samson, vice-president of research at the Institute for Research on Public Policy.

Along with the contacts for difference, she noted that details are scarce about how the $15 billion Canada Growth Fund will be spent.

The government announced in the budget that the fund will be administered independently by the Public Sector Pension Investment Board, with money starting to flow in the first half of the year, but didn't provide guidance on priority areas.

Samson said it was good the government isn't trying to direct the money itself, but worried that pension fund managers are too cautious to put the money in the bold projects needed.

"We need projects that are more on the cutting-edge, that are riskier."

The government also pushed down the road any commitments on biofuels such as sustainable jet fuels, which surprised Samson as Canada is currently exporting the raw wood pellet feedstock and knows companies have projects ready to go.

The budget was also notable for what wasn't in it for the oil and gas industry. While it did tweak last year's carbon capture incentives, it didn't go as far as some were pushing for, while the emissions cut-off for hydrogen production will likely exclude most carbon-capture based hydrogen projects.

"Oil and gas did not get a lot of what I think it wanted in this," said Samson.

The lack of funding comes as climate advocacy groups have pushed against support for both programs as wasteful projects that don't achieve the emission cuts needed in the near term, while also pushing against support for an industry that has reported record profits.

The government has also framed the budget as one of fiscal restraint that it hopes will allow private capital to do much of the heavy lifting to keep Canada in the running.

"Canada must either meet this historic moment, this remarkable opportunity before us, or we will be left behind as the world's democracies build the clean economy of the 21st century," said Freeland.

This report by The Canadian Press was first published March 28, 2023.

U.S. offers cash to Canadian critical minerals projects during Biden's visit

Originally posted on cbc.ca

There was a pot of gold at the end of President Joe Biden's jaunt to Canada. It's going to Canada's mining sector.

The U.S. military will deliver funds this spring to critical minerals projects in both the U.S. and Canada. The goal is to accelerate the development of a critical minerals industry on this continent.

The context is the United States' intensifying rivalry with China.

The U.S. is desperate to reduce its reliance on its adversary for materials needed to power electric vehicles, electronics and many other products, and has set aside hundreds of millions of dollars under a program called the Defence Production Act.

The Pentagon already has told Canadian companies they would be eligible to apply. It has said the cash would arrive as grants, not loans.

On Friday, before Biden left Ottawa, he promised they'll get some.

U.S. President Joe Biden addresses Parliament in Ottawa, Canada, on March 24, 2023. (Kevin Lamarque/AFP/Getty Images)

The White House and the Prime Minister's Office announced that companies from both countries will be eligible this spring for money from a $250 million US fund.

Which Canadian companies? The leaders didn't say. Canadian officials have provided the U.S. with a list of at least 70 projects that could warrant U.S. funding.

Biden also said Canadian semiconductor projects would be eligible for access to another Defence Production Act program.

"Our nations are blessed with incredible natural resources," Biden told Canadian parliamentarians during his speech in the House of Commons.

"Canada in particular has large quantities of critical minerals that are essential for our clean energy future, for the world's clean energy future.

"And I believe we have an incredible opportunity to work together so Canada and the United States can source and supply here in North America everything we need for reliable and resilient supply chains."

Canada has also promised billions of dollars to the sector. One participant at a recent Pentagon briefing in Washington said the U.S. funding would reassure potential private-sector investors that a given project has U.S. military backing.

It's not clear which types of jobs these projects would create in Canada.

Biden may have triggered some cringes in Canadian political circles when he appeared to suggest the value-added transformation jobs from this future sector would go to the U.S.

He cast it as an ideal partnership: Canada would extract the minerals, Americans would build things with them.

"You guys – we don't have the minerals to mine, you can mine them," he said. "You don't want to produce, I mean, turn them into product."

Cut the red tape, mining sector says

Another unknown is how quickly this sector will grow in Canada, and whether it can ramp up in time for this country to become a major player in providing raw materials for growing fleets of electric vehicles.

Some business groups have told the Canadian government it must speed up permitting times or risk seeing this window close for Canada.

The Mining Association of British Columbia, for example, has proposed numerous measures to alleviate what it called interminable delays.

"The permitting and authorization processes that regulate mining projects are too cumbersome, untimely and inconsistent with the urgent need," it said in a recent briefing paper.

The federal government has acknowledged this issue and has promised to speed things up.

"It cannot take us 12 to 15 years to open a mine in this country. Not if we want to achieve our climate goals," Environment Minister Jonathan Wilkinson said late last year.

Canada budget to have tax credit for equipment used to produce EVs – sources

Originally posted on Mining.com

Canada’s Foreign Minister Chrystia Freeland. Photo by Freeland’s press office

Canada will introduce in its budget next week a 30% investment tax credit to boost clean-tech manufacturing, especially in the electric vehicle (EV) supply chain, two government sources familiar with the document said on Thursday.

The tax credit for capital investments in manufacturing equipment will be a “significant piece” of a bundle of measures aimed at putting Canada’s green-transition effort on the same level as the United States, said one source.

The credit will be available for future investments in equipment used to extract and process critical minerals used in EVs, a second source said, and to purchase equipment used in manufacturing along the entire EV supply chain, including for batteries.

In addition, the tax credit will be able to be used to buy equipment to produce nuclear energy fuels and heavy water, for making electrical energy storage, and for producing solar panels or wind turbines, the second source said.

Finance Minister Chrystia Freeland will present the 2023-2024 fiscal year budget to parliament on Tuesday. Neither source was authorized to speak on the record. A finance ministry spokesperson declined to comment.

Freeland has promised to bolster Canada’s green energy stimulus after the US last year passed the Inflation Reduction Act (IRA), which provides massive incentives for those who invest in clean technology there.

“In an ideal scenario, this will incentivize expanded critical minerals extraction and processing in Canada, and ideally a lot of that will then be purchased and fed into a growing net-zero manufacturing base in the US,” the first source said. US President Joe Biden is due to arrive in Ottawa on Thursday for an official visit that officials say will include an agreement between the two countries to enhance cooperation clean energy and technologies.

Last year, Canada budgeted C$3.8 billion ($2.8 billion) to scale up exploration and infrastructure for critical minerals. Pierre Gratton, president and CEO of the Mining Association of Canada, said more investment is badly needed. Countries across the globe are scrambling to take advantage of a rapid shift to low-carbon energy. Canada has an abundance of the critical minerals used to produce EVs.

“The US does need us… and right now, we’re not on track to deliver,” Gratton said. “So these measures, if they turn out to be in the budget, will help us make sure we can deliver.” Canada sends three-quarters of its exports south of the border, and the automobile industries of the two countries are highly integrated.

Neither source put a price tag on the measure, but they did say it would not apply to projects where investments have already been agreed, such as the two Canadian battery plants planned by carmakers Volkswagen and Stellantis NV.

Canada has limited financial firepower compared with what the US put forward in the IRA, which many experts say will lead to more than $1 trillion in investment.

Earlier this month, a source told Reuters that green transition budget measures would focus on increasing the capacity of the electricity grid, on battery manufacturing and on mass timber construction, without providing details.

Last autumn, Canada announced investment tax credits for companies that purchase finished clean energy systems, like solar panels. Instead, the new tax credit will apply to manufacturers buying equipment to build things like solar panels.

“It’s about building out the industrial base in Canada,” the second source said.

($1 = 1.3659 Canadian dollars)

(By Steve Scherer; Editing by Denny Thomas, Bill Berkrot and Marguerita Choy)

Europe turbo charges its critical minerals drive

Originally posted on Mining.com

The European Union has unveiled the accelerator in its drive to reduce the bloc’s import dependency for critical minerals and metals.

The Critical Raw Materials Act (CRMA) “will significantly improve” Europe’s domestic extraction, processing and recycling capacity for metals such as lithium and rare earths, according to Ursula von der Leyen, president of the European Commission.

The Act comes with targets for production and for reducing dependency on any single third country. China currently dominates the supply chain for many of the entries on Europe’s list of “strategic” metals.

The EU is also playing catch-up with the United States, which is already investing heavily in critical metals capacity under the aegis of the Defense Production Act and the Inflation Reduction Act.

Europe may, however, have given itself a competitive edge by moving to streamline project permitting, a tortuous process that often drags on for years before the first shovel hits the ground.

(Moving) targets

The CRMA covers a subset of the EU’s critical minerals list, with particular focus on battery metals like lithium, nickel, cobalt and manganese and magnet inputs such as boron and rare earths.

Copper is on the list as an enabler of all things electric but aluminum and zinc aren’t, which is a striking omission given the recent shrinkage of European production capacity.

Germany’s Speira has joined the list of casualties, this month announcing the full closure of its Rheinwerk aluminum smelter due to high energy costs.

“Today’s strategic raw materials list must not be the finished picture,” warned Evangelos Mytilineos, president of industry group Eurometaux.

It probably won’t be. The CRMA includes a provision for periodically updating the list to reflect evolving economic importance and supply risks across the critical metals spectrum.

For those metals on the list the target is for the region to mine 10%, process 40% and recycle 15% of what it consumes annually by 2030. By which time not more than 65% of any strategic metal’s consumption will be able to come from a single third country.

These are ambitious targets given Europe currently sources 97% of its magnesium in China, which also has a complete monopoly on the processing of heavy rare earths and graphite.

Europe’s lithium extraction can in theory meet the 10% target but it hinges on multiple new projects, many of them using innovative technology.

Recycling lithium-ion batteries is also a technical challenge that has to be resolved at scale to meet the 15% recycling target.

Permitting

In terms of maximizing domestic mining and processing capacity, Europe is following the United States in instructing all national governments to go back and look at what may have been left behind in tailings ponds and historic mine sites.

Operators of existing mines and plants should prepare an economic assessment study of what they’re losing in “waste” streams. It’s a policy that has already significantly closed the US dependency gap for tellurium and scandium.

However, Europe has overtaken the United States in one key area, aiming to streamline the permitting of “strategic” projects to ensure a maximum time-line of two years for mines and one year for processing plants.

All such projects should be considered as being “in the public interest” by the relevant national authority when considering environmental impact.

The US Administration has come under fire for using the Inflation Reduction Act to incentivize domestic mining while simultaneously blocking development of mines on federal land. The green-on-green environmental clashes seem set to continue until there is a long-overdue rewrite of the General Mining Act of 1872.

Collective buying and stockpiles

Many strategic metals markets are opaque, not easily financially hedged and concentrated on the supply side, according to the CRMA. All of which “increases the negotiating power of sellers and increase prices for buyers.”

It calls for the Commission to set up a system for collective purchasing by interested buyers, a mechanism already trialed in the gas market.

It also recommends the accumulation of strategic metal stocks to buffer against unexpected supply disruptions. Europe has no strategic metal inventory, unlike the United States, China and South Korea.

Member states may have their own stockpiles and “as a first step and considering the lack of relevant information,” the 27 countries in the bloc should report to the Commission what, if anything, they are holding.

Given such a humble starting point, it seems unlikely EU strategic metal reserves are going to come any time soon, if they come at all.

Metallic arms race

The EU accepts it will never be fully self-sufficient in most if any of the metals it’s identified as being critical to its industrial and defense sectors.

The CRMA advocates diversifying supply in favor of “reliable partners” and creating “mutually beneficial partnerships with emerging market and developing economies.”

It represents a further tectonic decoupling of global supply chains.

What started as a response to China’s dominance of critical metals supply has been accelerated by Russia’s invasion of Ukraine.

Russia has historically been a major supplier of aluminum, copper and nickel to Europe’s industrial sector to the extent that the EU has to date held back from sanctioning Russian material even as the United States imposes penal import duties.

But the metals world is clearly starting to split between West and the East.

It’s a messy process, witness the dispute between the EU and the United States over the exclusion of European products from the electric vehicle subsidies introduced in the Inflation Reduction Act.

That particular hurdle may shortly be cleared, German newspaper Handlesblatt reporting that a draft agreement has been reached.

It is evidently in neither side’s interest to compete with each other in the context of reducing resource ties with China and Russia.

Assuming future trans-Atlantic harmony can be achieved, something akin to a metallic NATO will start to take ever clearer shape.

(The opinions expressed here are those of the author, Andy Home, a columnist for Reuters.)

The impact of vehicle sizes on mineral demand in the EV market

Originally posted on Mining.com

Source: Benchmark Mineral Intelligence

As the electric vehicles (EV) market grows, a debate is developing about the amount of minerals needed to supply the demand for EV batteries.

Following the US’ push for electrification with the Inflation Reduction Act, the European Union recently unveiled its Critical Raw Materials Act to “significantly improve” domestic extraction, processing, and recycling capacity for metals such as lithium and rare earths.

Other nations like Canada and South American countries are also discussing how to benefit from the expanding market.

The infographic above by Benchmark Mineral Intelligence demonstrates how different models and battery types impact critical mineral demand.

While a Tata Motors Tiago battery contains only 1.1kg of lithium carbonate equivalent (LCE), a Tesla Semi truck requires over 500kg of LCE to operate.

Prime Minister Trudeau and President Biden Joint Statement

Originally posted on pm.gc.ca

Canada and the United States celebrate our progress under the Roadmap for a Renewed U.S.-Canada Partnership over the past two years and reaffirm our historic alliance, steadfast friendship, and commitment to overcome the daunting challenges of today and realize the full potential of the relationship in the future. Our enduring partnership is based on a mutual commitment to shared security, shared prosperity, and shared democratic values, including the importance of fighting climate change and an abiding respect for human rights and the rule of law. As the closest of friends and allies, we remain committed to making life better for people on both sides of our shared border and to building a more free, equitable, secure, and prosperous world.

To that end, Canada and the United States will work together to:

1.Catalyze Clean Energy and Create Good Jobs: Deepening economic integration, accelerating the deployment of clean technologies, and workforce development are essential to building a more sustainable and globally competitive economy for American and Canadian workers, including through continued implementation of the U.S.-Mexico-Canada Agreement.

Prime Minister Trudeau and President Biden highlighted Canada’s Emissions Reduction Plan and the U.S. Inflation Reduction Act as foundational elements to leading the clean energy future through robust clean energy industrial policies that help mobilize technological innovation, bolster resilient supply chains, strengthen our respective economies and expand the middle class, while keeping our environment healthy for future generations. Canada is moving forward with an enhanced plan to support a clean economy future, including with a new investment tax credit for clean technology manufacturing in addition to tax measures that support clean hydrogen and clean technology adoption. As the implementation of these plans proceed, the United States and Canada will work together toward an integrated North American approach that benefits U.S. and Canadian workers, suppliers, and products.

Canada and the United States launched a one-year Energy Transformation Task Force chaired by the U.S. Special Presidential Coordinator for Global Infrastructure and Canada’s Deputy Prime Minister to work across the spectrum of the clean economy. The task force will accelerate cooperation on critical clean energy opportunities and supply chains, including but not limited to, securing and strengthening renewable energy and electric vehicle supply chains, critical minerals and rare earths, grid integration and resilience, advanced and conventional nuclear energy and other areas that advance our collective energy security, and to avoid and reduce disruptions to our integrated and mutually supportive supply chains.

Canada and the United States have built the world’s largest market-based energy trading relationship, which provides a firm foundation as we strive to reach net-zero greenhouse gas emissions. Both countries will work to harmonize charging standards and develop cross-border alternative fuel corridors, drawing on USD $7.5 billion in the U.S. Bipartisan Infrastructure Law and CAD $1.2 billion in Canadian funding to build a network of electric vehicle fast chargers and community charging options on both sides of the border.

Building on Canadian and U.S. commitments to achieve net-zero power grids by 2035 and to accelerate efforts to phase down new, unabated coal power generation facilities, both countries intend to propose regulations before this fall that will reduce greenhouse gas emissions from their respective sectors. The United States and Canada also intend to work with other major energy importers and exporters to develop an internationally aligned approach to measurement, monitoring, reporting, and verification for lifecycle methane and CO2 emissions across the fossil energy value chain.

Canada and the United States will work together to address the climate impact of goods, promote North American trade of low-emissions goods, including the promotion of common approaches for trade in low emissions goods, including green steel and aluminum.

On civil nuclear engagement, Canada will join the Foundational Infrastructure for Responsible Use of Small Modular Reactor Technology (FIRST) program, providing funding and in-kind support. Canada and the United States will also coordinate efforts to develop secure and reliable North American nuclear fuel supply chains and build broader partnerships with longstanding allies and partners, both of which will help to ensure access to low enriched uranium, including High-Assay Low Enriched Uranium.

2.Strengthen Resilience of Critical Mineral and Semiconductor Supply Chains: Canada and the United States will work together to create a strong, environmentally responsible, and resilient North American critical minerals supply chain. We are committed to identifying, securing, and developing critical minerals extraction, processing, manufacturing, and recycling opportunities in both countries to diversify supply chains essential to clean energy, electric vehicles, semiconductors, aerospace, and defense, among other sectors, that meet strong environmental, sustainability, worker, health and safety, Indigenous and Tribal consultation and partnership, and community engagement standards.

Canada and the United States are taking a significant step toward the creation of reliable and sustainable critical mineral supply chains that are vital to our economic and national security and demonstrate the commitment of the United States to support Canadian companies in the energy economy.

Last year, the United States announced USD $250 million of Defense Production Act Title III funding for U.S. and Canadian companies to mine and process critical minerals for electric vehicle and stationary storage batteries, with awards to U.S. and Canadian companies to be announced this spring.

The Canadian Critical Minerals Infrastructure Fund will make CAD $1.5 billion available to support clean energy and transportation infrastructure projects necessary to accelerate critical minerals production and an additional CAD $1.5 billion through the Strategic Innovation Fund to support advanced manufacturing, processing, and recycling.

With the passage of the CHIPS and Science Act, Canada and the United States will facilitate investment to promote secure and resilient semiconductor supply chains, creating jobs in both countries. Both countries will advance a cross-border packaging corridor, beginning with Canada and IBM providing a significant investment to develop new and expanded packaging and testing capabilities at its Bromont facility as part of a Memorandum of Understanding

To strengthen advanced packaging for semiconductors and printed circuit boards in North America, the United States announced an additional USD $50 million in Defense Production Act funding for U.S. and Canadian companies to advance packaging for semiconductors and printed circuit boards, with Canada to provide up to CAD $250 million for semiconductor projects from the Strategic Innovation Fund in the near term. We are also establishing an Advanced Technology Data and Security Dialogue and intend to deepen our collaboration on shared priorities in quantum information science and technology.

3.Protecting Our Shared Waters and the Arctic: Canada and the United States committed to fight climate change and build net-zero economies, conserve biodiversity, and protect fragile ecosystems, including in transboundary waters and the Arctic.

Recognizing the vulnerability of the unique, shared Arctic ecosystem, Canada and the United States committed to advancing conservation, environmental protection and resilience in partnership and consultation with the Indigenous peoples and populations, and furthering work under agreements and treaties established around the movement of shared species.

Canada and the United States further committed to initiating dialogue with other Arctic Nations and Indigenous peoples to advance conservation and sustainable economic development in the Central Arctic Ocean, and recognized the need to conserve and protect Arctic ecosystems and reduce localized emissions of carbon dioxide, methane, and black carbon in the Arctic to complement our global mitigation efforts. The two countries will collaborate to prepare for, prevent, and respond to oil spills and other environmental disasters in the Arctic.

Canada and the United States announced a renewed commitment to preserving and restoring our shared national treasure, the Great Lakes. The United States welcomed Canada’s announcement of a new, historic investment of CAD $420 million over the next decade as part of this shared responsibility to protect and restore the world’s largest freshwater ecosystem. The U.S. Bipartisan Infrastructure Law provided the largest single investment in the Great Lakes in history, with USD $1 billion for cleanup and restoration activities.

Canada and the United States will intensify their work over the coming months toward agreement on a modernized treaty regime that will support a healthy and prosperous Columbia River Basin. We will focus on flood risk management, power generation, and environmental benefits that are shared equitably by both countries and the Indigenous peoples and Tribal nations, communities, and stakeholders in this watershed. The Columbia River is a vital shared resource that underpins many lives and industries on both sides of the border and the watershed requires our attention and prompt coordination.

Canada and the United States also intend to reach an agreement in principle by this summer to reduce and mitigate the impacts of water pollution in the Elk-Kootenay watershed, in partnership with Tribal Nations and Indigenous Peoples, and in order to protect the people and species that depend on this vital river system.

4.Advancing Diversity and Inclusion: Recognizing the central importance of inclusion and equal opportunity to our democracies, Canada and the United States will continue to work toward fair and inclusive policies that benefit all citizens, regardless of sex, gender, or sexual orientation; race, ethnicity, or religion; age; disability; or geography.

Building on previous bilateral and North American commitments, the Leaders reaffirmed their shared determination to promote equality and ensuring everyone lives free from discrimination, harassment, or violence. Canada and the United States remain committed to ensuring the full, equal, and meaningful participation of marginalized communities in our societies.

The Leaders reaffirmed their shared commitment to promoting gender equality and empowering women and girls as essential for achieving a more peaceful, inclusive, and prosperous world. They underscored the importance of continued cooperation on the advancement of gender equity, including with respect to child benefits, early learning and childcare, pay equity, and women’s entrepreneurship, among other issues.

5.Bolster Global Alliances: Canada and the United States are committed to the security of our treaty allies, including through the North Atlantic Treaty Organization (NATO), and to supporting our partners around the world. We are even stronger through our collaboration at and with the United Nations and other international organizations, alliances, and groups, including the G7, G20, the Five Eyes, and the Organization of American States.

We condemn Russia for its illegal, unjustifiable, and unprovoked war against Ukraine, and will continue imposing economic costs on Russia, while maintaining our unwavering support for Ukraine for as long as it takes.

Canada and the United States acknowledge the serious long-term challenge to the international order posed by the People’s Republic of China, including disruptive actions such as economic coercion, non-market policies and practices, and human rights abuses. While we will cooperate with China in areas of mutual interest, such as on climate change, we remain committed to ensuring our ability to compete effectively with China on a level playing field. Canada and the United States will also continue to cooperate on countering foreign interference in our societies in a manner that reflects our shared democratic values.

We emphasize that our basic positions on Taiwan remain unchanged, and reiterate the importance of maintaining peace and stability across the Taiwan Strait as an indispensable element of security and prosperity in the international community. We encourage the peaceful resolution of cross-Strait issues.

The Prime Minister and the President reaffirmed their commitment to the Americas Partnership for Economic Prosperity, and welcomed the first U.S.-Canada Indo-Pacific Strategic Dialogue on March 10 and will cooperate to promote a free, open, prosperous, secure, and resilient Indo-Pacific.

Canada and the United States are working together to support countries around the world as they develop their economies to deliver inclusive and resilient growth, while fostering sustainable pathways to net zero emissions. Through the G7 Partnership for Global Infrastructure and Investment, we are collaborating to unlock public and private capital for quality infrastructure to create lasting positive impacts for low- and middle-income countries and support sustainable development, as well as benefit partners’ economic security and global supply chains. We are also advancing an ambitious agenda to evolve the multilateral development banks, starting with the World Bank, to better respond to global challenges, while also enhancing their work on poverty alleviation and meeting the Sustainable Development Goals.

Canada and the United States also remain concerned about deteriorating security in Haiti, committed to increasing international support for the Haitian people, including through security and humanitarian assistance, enhanced support for the Haitian National Police, and by holding accountable those who undermine Haiti’s stability.

6.Invest in Our Collective Defense and Security: Our highest priority is to protect our citizens and our sovereign territory. We will invest in the modernization of the North American Aerospace Defense Command (NORAD), including specifically:

As part of a CAD $6.96 billion investment in surveillance system modernization, procuring and fielding two next generation Over-the-Horizon Radar (OTHR) systems covering the Arctic and Polar approaches, the first by 2028 to enhance early warning and domain awareness of North American approaches;

CAD $7.3 billion in investments in the northern forward operating locations to support 5th generation aircraft and mobility/refueling assets, which capabilities should be in place prior to the arrival of the F-35 aircraft, including airfield improvements to accommodate aircraft personnel, fuel, and munitions, to ensure NORAD’s ability to deter and defend against emerging threats to our air and sea space and compete with China and Russia for years to come.

The Prime Minister confirmed that the funding for these investments would come from Canada’s planned investments in defense infrastructure. These Canadian and U.S. efforts will bolster NORAD’s ability to detect threats earlier and more precisely and respond effectively. In the face of global threats, the Leaders acknowledged the importance of investment in modern, ready, and capable forces in line with their commitments to NATO under the 2014 Wales Summit Defence Investment Pledge. Such investments enable effective contributions to NATO, United Nations, and other global missions.

The Leaders recognized the need to work in close collaboration to combat all criminal activity in our combined jurisdiction. The Cross-Border Crime Forum is key to the safety of both countries, by facilitating cooperation to reduce violent extremism, child sex exploitation, cross-border smuggling, and firearms violence on both sides of the border.

Cyber threats can impact both Canadians and Americans, particularly when directed at cross-border systems on which we all rely.

To better protect against these threats, we will deepen our cooperation on driving improvements to the cybersecurity and resiliency of our critical infrastructure.

We will focus on two key sectors – pipelines and electricity – due to their criticality to our economies and their cross border nature. Further, we reiterate that in each of our countries, should an adversary choose to target critical infrastructure systems, we will both respond.

The opioid overdose crisis is having devastating health and economic consequences in our societies. We are united in our resolve to disrupt the illicit production and distribution of synthetic opioids like fentanyl and its precursor chemicals while augmenting our public health response.

Canada and the United States will expand multi-agency cooperation to improve intelligence sharing on cross-border fentanyl and precursor chemical trafficking to support interdictions and investigations, as part of our effort to bolster cooperation under U.S.-Canada Opioids Action Plan.

Canada will join the United States as it builds a global coalition against synthetic drugs, underscoring Canadian and U.S. leadership in response to this shared security and public health challenge. Canada and the United States reaffirm their commitment from the tenth North American Leaders’ Summit to work with Mexico trilaterally to defeat the synthetic opioid crisis.

7.Manage Migration Collaboratively: The Los Angeles Declaration on Migration and Protection enshrines our belief that irregular migration requires a regional approach centered on expanding legal pathways and humane border management and recognizes that we must address the underlying economic and security drivers of migration. Canada and the United States remain committed partners in advancing the principles of the Declaration.

As part of its commitment to these principles, Canada will welcome an additional 15,000 migrants on a humanitarian basis from the Western Hemisphere over the course of the year to continue expanding safe, regular pathways offered throughout the hemisphere as an alternative to irregular migration, with a path to economic opportunities

Additionally, Canadian and U.S. officials are now poised to implement an agreement to apply the terms of the Safe Third Country Agreement to asylum seekers who cross between ports of entry, which we anticipate will deter irregular migration at our shared border. We will remain in close coordination as we work to implement this new agreement.

Vanadium Reserves by Country

Originally posted on Investingnews.com

Vanadium reserves worldwide exceed 63 million MT, according to the US Geological Survey’s latest report on the metal.

The industrial metal occurs in deposits of phosphate rock, titaniferous magnetite and uraniferous sandstone and siltstone. Significant amounts of vanadium can also be found in bauxite and carboniferous materials like coal, crude oil, oil shale and tar sands. Generally vanadium is mined as a by-product, and for that reason it is difficult to accurately determine world reserves.

That said, estimates are available, and investors interested in vanadium may want to know which countries are thought to have the highest vanadium reserves. Read on to learn about the top three — interestingly, these countries are also the largest producers of vanadium.

1. China

Vanadium reserves: 9 million MT

China has the largest reserves of vanadium and produced 42,000 MT of the metal in 2016. The country also consumes the most vanadium and has the fastest-growing rate of vanadium consumption. Indeed, between 2006 and 2014, China’s vanadium consumption grew by 217 percent.

About 91 percent of vanadium produced in China is used to make steel. According to Roskill’s most recent Vanadium Quarterly Review, Chinese steel production will grow by 0.2 percent annually to 2025.

2. Russia

Vanadium reserves: 5 million MT

Russia, like China, extracts vanadium from slag produced by steel smelters or as a by-product of uranium mining. In 2016, Russia produced 16,000 MT of vanadium.

In April, Russia’s minister of industry and trade, Denis Manturov, told Metal Bulletin that the country’s government is planning to significantly increase the nation’s vanadium production. A spokesman for Manturov said it will achieve this expansion by paying subsidies to the country’s largest vanadium producers and providing tax breaks.

3. South Africa

Vanadium reserves: 3.5 million MT

Vanadium production in South Africa came to 12,000 MT last year, and was hindered by the closure of an iron and vanadium mine in 2015.

The mine closure forced a major vanadium product producer to suspend its operations, and left the country with just two major vanadium producers. Additionally, a private vanadium products producer in Austria that relied on imported vanadium from South Africa is expected to have reduced output moving forward.

Honorable mentions

Australia has 1.8 million MT of vanadium reserves and the US has 45,000 MT. The US Geological Survey notes that all of the US demand is met by imports from other countries, even though the US has enough domestic resources to supply most of its domestic needs. Data on the total amount of vanadium reserves in Brazil is not available, but the country produced an estimated 6,000 MT in 2016.

Vanadium Uses: Alloys and More

Originally posted on Investingnews.com

Curious about vanadium and vanadium uses? About 90 percent of vanadium is used to make steel, but the metal has other key applications as well.

Vanadium is a silvery-grey transition metal that’s currently produced in only four countries: China, Russia, South Africa and Brazil. The metal is not found on its own in nature, but can be separated from about 65 minerals, including carnotite, roscoelite, vanadinite, mottramite and patronite.

In terms of characteristics, vanadium has good structural strength and is ductile; in addition, it’s harder than most metals and steels, though due to its ductility some sources refer to it as soft. Vanadium is also resistant to corrosion, and remains stable against alkalis, along with sulfuric and hydrochloric acids. It oxidizes at about 660 degrees Celsius, becoming vanadium pentoxide, or V2O5.

Those qualities give the metal many uses, with the main vanadium use being in the production of alloys like ferrovanadium. That said, demand for vanadium from the battery sector is expected to grow, while vanadium pentoxide is used in ceramics and as a catalyst in certain chemical reactions. Read on for a more detailed overview of vanadium uses.

Vanadium uses: Alloys

As mentioned, most vanadium produced today is used to make alloys. In fact, current estimates indicate that about 90 percent of vanadium is used to make ferrovanadium, an alloy of iron and vanadium.

Those new to the vanadium space might reasonably wonder why so much of the metal is used for just one thing. To see why that’s the case, it’s important to understand what exactly ferrovanadium is. Put simply, ferrovanadium is one of many different ferroalloy types, and ferroalloys themselves are alloys of iron that have a high proportion of one or more other element. Other common ferroalloys include ferromagnesium, ferromanganese and ferrochromium.

Ferroalloys are important in the world today because they’re used in the production of steel and other alloys. Steel, of course, has myriad industrial applications; for instance, it’s used in infrastructure, such as roads and railways, as well as to make appliances and buildings. Another vanadium use is in ships, and it is also used in the aerospace industry and in pipelines, among many others.

Steel has different characteristics depending on what ferroalloy it’s made with, and ferrovanadium is particularly desirable in steelmaking. That’s because only a small amount of vanadium can significantly increase the strength, hardness and high temperature stability of steel.

Vanadium uses: Other

It’s clear that most of the metal goes toward the production of alloys, but there are other vanadium uses worth mentioning. For instance, as noted above, vanadium pentoxide is used in ceramics and as a catalyst in certain chemical reactions. Specifically, it’s used to make sulfuric acid and maleic anhydride, and is added to glass to make a green or blue tint.

Vanadium pentoxide is also used to permanently fix dyes to fabric, and can be mixed with gallium to form superconductive magnets.

On a different note, vanadium use is gaining traction in the energy space. Some believe that in the future the energy sector may become a big source of demand for vanadium, suggesting that as the world shifts toward using more sustainable power, vanadium-redox batteries (VRBs) will become increasingly widespread. VRBs are a type of flow battery designed to safely store and release large amounts of energy.

That said, VRBs have had a rocky start — though the first VRB was created in the 1980s, until 2006 companies weren’t allowed to produce them due to initial patent terms. Since then, work on VRBs has moved forward a little more quickly, with countries like Japan and Germany providing subsidies for companies working in the energy storage space.

Interest in VRBs has ramped up in particular over the last couple of years, although the technology has been overshadowed by developments in the lithium-ion battery industry. “Vanadium flow has yet to have its Tesla (NASDAQ:TSLA) moment, and therefore it still flies under the radar,” Simon Moores of Benchmark Mineral Intelligence told Bloomberg in January 2018.

VRBs last longer than lithium-ion batteries and can be charged and discharged over and over without any effect on performance. But they are intended for larger-scale applications, and some experts have suggested that VRB makers are vulnerable because they depend heavily on a niche metal.

Vanadium Market Forecast: Top Trends That Will Impact Vanadium in 2023

Originally posted on Investingnews.com

What’s ahead for the vanadium space? Read on to see what market watchers see for the vanadium forecast in 2023.

Heading into 2022, experts were expecting vanadium demand to increase on battery segment attention.

While most vanadium is used in China for steel applications, particularly the high-strength, low-alloy steel used to make construction rebar, the metal has a growing role in batteries that is attracting interest.

As the year comes to an end, what can investors expect for vanadium in 2023? Read on to learn more about vanadium’s performance in 2022, as well as what analysts and market watchers are forecasting for next year.

How did vanadium perform in 2022?

As mentioned, at the end of 2021, analysts were expecting vanadium demand to grow in 2022. But the first few months of the new year were shocking for metals markets as Russia's invasion of Ukraine brought volatility to the commodities sector.

All in all, the story of the vanadium industry in 2022 was almost exclusively determined by the Russia-Ukraine conflict, Willis Thomas and Connell Murphy of CRU Group told the Investing News Network (INN).

“Vanadium has not been affected to the same extent many other commodities have been in the wake of the conflict, but initial sentiment saw prices almost double in March due to the invasion,” they said. “This was due to the risk of losing the large supply of ferrovanadium into the European steel market through the Russian-owned Evraz.”

Sanctions hit Roman Abramovic, the biggest shareholder of Evraz, a major vanadium producer with assets in Russia and Czechia, leading to the resignation of the company's entire board.

“Due to Evraz trading vanadium oxide into the Czech Republic, where it is then processed into ferrovanadium, however, very little impact has been seen,” the CRU analysts said. “This has been confirmed by the market, with prices dropping since March and resting back at pre-conflict prices for the past four months.”

Commenting on the performance of vanadium in 2022, Jack Bedder of Project Blue also said that despite initial fears, there has been no meaningful disruption of vanadium flows as a result of the Russia-Ukraine conflict or sanctions.

“We expected more subdued demand from China ― and this proved to be the case,” he said. “(There were) no major surprises on the supply side ― although of course the Russia-Ukraine war was unexpected.”

In the first half of the year, the market also moved from worrying about supply risks due to the ongoing Russia-Ukraine war; instead, demand risks took over as China’s lockdowns impacted the sector.

“Demand in China has been lower than expected as a result of steel production curbs in China enforced due to the Winter Olympics, and extended COVID-19 shutdowns,” Bedder said back in June.

Lockdowns in China impacted demand, but not as much as some had anticipated during the first half.

“Lower steel production for rebar and some slowdowns in battery projects came as a result, with delays more than anything,” CRU’s Thomas told INN back in June.

Speaking about the battery sector, Thomas said there have been more investments for electrolyte capacity, so there will certainly be increased demand moving forward. “Vanadium battery demand expectations are notoriously difficult to meet, with issues of supply and for the battery projects themselves being common,” he said.

Vanadium is a key metal used in vanadium redox batteries (VRFBs), which are a viable option for large-scale storage because they are able to provide hundreds of megawatt hours at grid scale.

In contrast to the volatility of H1, a steady and subdued market persisted with much lower prices in the second half of the year.

“As is the case with all ferroalloys, demand from the steel sector was subdued owing to trends in China, principally its zero-COVID strategy and faltering property and construction sectors,” Bedder said. “Vanadium prices were impacted accordingly and fell back.”

But in the last quarter, activity picked up a little. “Rebar stocks are slowly being drawn down, although restocking is typical of this time of year with producers preparing for higher demand to come,” Bedder said.

While steel demand is down, aerospace demand for vanadium (and other metals) was a bright spot in Q4.

“In addition, more announcements of VRFB electrolyte capacity and planned installations continue to suggest that the technology is gathering momentum,” Bedder added.

What factors will move the vanadium market in 2023?

As 2023 kicks off, global demand for vanadium is once again expected to increase, according to CRU, as many industries ― steel, chemicals, aerospace, batteries and more ― are still seeing growth coming out of COVID-19.

“(There is) steady growth seen in chemicals, temporary growth seen in the steel sector and accelerating growth seen in both aero and batteries,” Thomas and Murphy said.

Similarly, Project Blue expects the overall market to grow at a CAGR of 2.7 percent over the 2021 to 2027 period, although it expects a 5 percent decline between 2021 and 2022.

“Over the five year horizon, demand in steel is set to increase, supported by high-strength, low-alloyed output and higher intensity of vanadium use,” Bedder said. Alloy demand growth is expected, but will be a slow recovery from COVID-19 impacts.

As a whole, the firm is not expecting demand to reach 2019 levels again until the late 2020s.

“Growth in chemicals demand will be moderate with no novel applications set to boost demand,” Bedder added.